Why Buy a 3d printer ?

Normally, a factory run of an item requires a fairly heavy investment. Manufacturers need to provide specified equipment and item molds, designed for one and only one kind of object. This cost is incredibly prohibitive for newcomers and small businesses, who can’t afford the initial down payment.

3D printers, on the other hand, don’t need to be modified for each kind of item you product. If you want to make an phone case one day and a PEZ dispenser the next, you just have to send a new file to the printer. No swapping out equipment, no changing molds to fit a new design. Just load a new cartridge, hit “print,” and see your creation come to life.

Even if you want to use traditional production methods, 3D printers can still be useful. As Financial Post notes, you can use printers to efficiently create variations on a prototype model, whic/h you can then use as the basis for the mold. Since the prototype doesn't have to be created by hand, you can make many small changes before you settle on one specific design.

As stated on http://www.buy3dprinter.org/small-companies-big-potential-manufacturing-3d-printers

Monday, March 31, 2014

Tuesday, March 4, 2014

Monday, March 3, 2014

March Production Run Ongoing

We have a limited supply of parts in stock to take orders for delivery by April 1.

65k Philippine pesos. We have Azteeg v1 boards and Arduino/Ramps boards. Your choice.

This is laser cut powder coated steel frame. Heated bed.

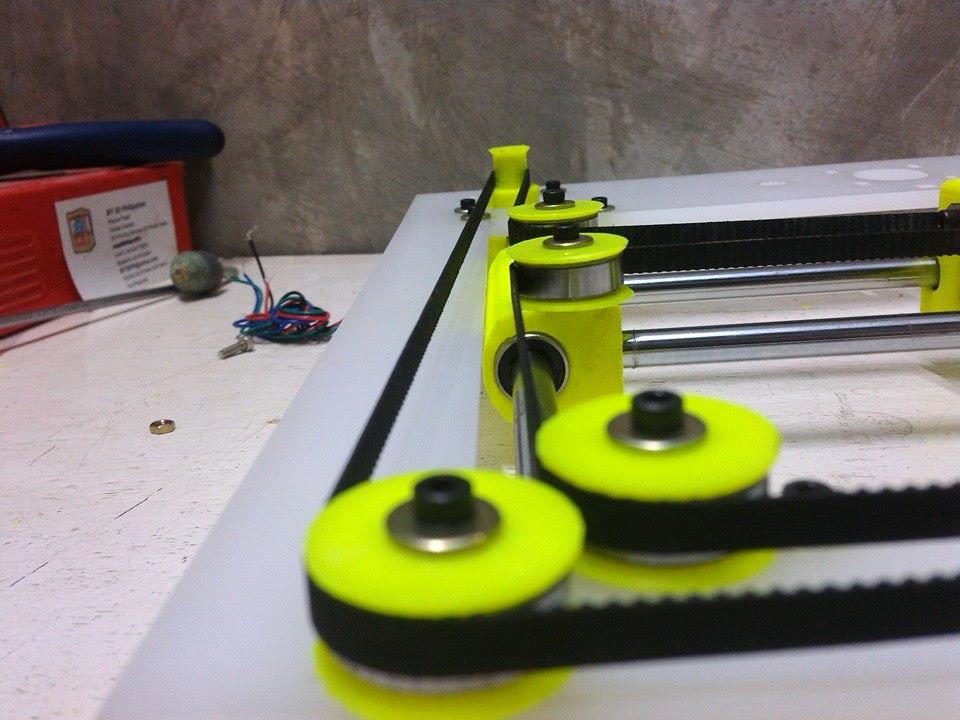

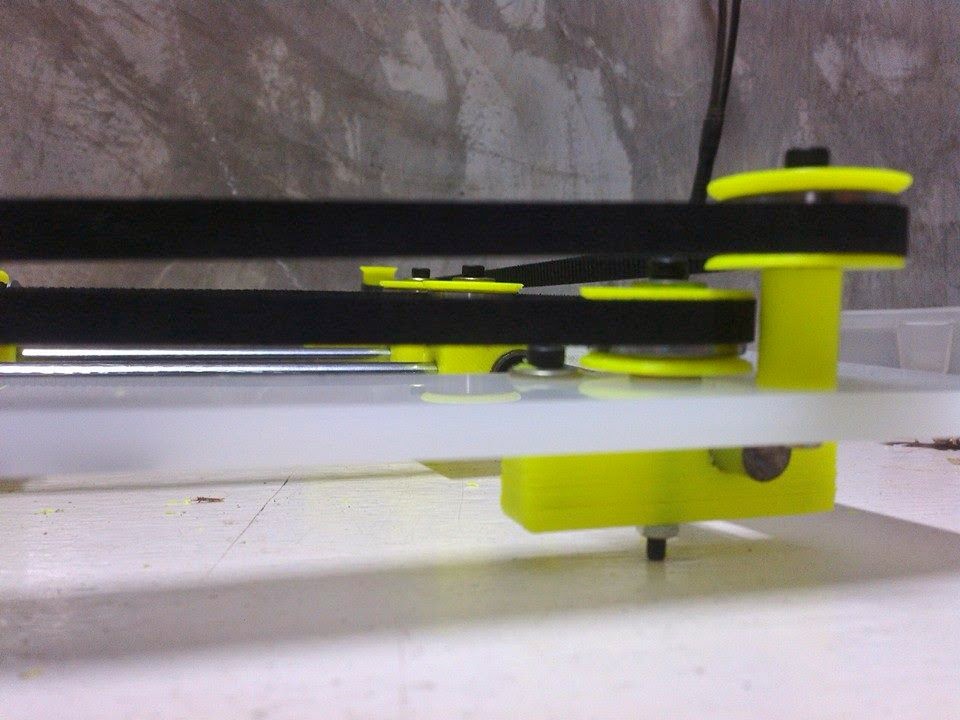

E3D hot ends. CoreXY geometry.

Assembled, calibrated and tested with a USB full of drivers and software.

65k Philippine pesos. We have Azteeg v1 boards and Arduino/Ramps boards. Your choice.

This is laser cut powder coated steel frame. Heated bed.

E3D hot ends. CoreXY geometry.

Assembled, calibrated and tested with a USB full of drivers and software.

Subscribe to:

Posts (Atom)